Hard Candy

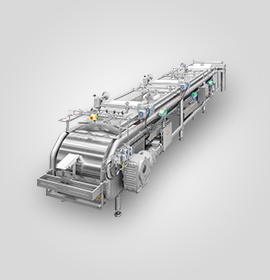

Hard candies comprise of a large variety of products. They can be formed using a chain die, rotary moulder or as deposited products. Product quality depends on many factors:

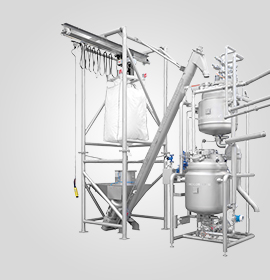

- Stabil process monitoring and control is essential for sustainable quality; ingredient weighting and mixing, temperature, flowrates and pressures

- The process inversion must be limited to a minimum; the shelf-life of the product depends on this

- Product diversity due to the use and combination of different sugar replacers

- For better shelf-life a higher total solids level is necessary in some recipes

- Diversity in shapes combined with different colors, flavors and fillings

- Via aeration masses can receive the look of a pulled product; fat fillings like peanut butter can be used for a laminated product

- Medicated products require a full documentation of all plant and process parameters to guarantee product quality